Understanding the Fundamentals of Welding Assessment to Make Sure Quality and Safety And Security

In the world of modern-day engineering, welding evaluation stands as a keystone for making certain both the quality and safety and security of structural developments. What are the subtleties of these inspection approaches that make them vital for preserving structural integrity?

Importance of Welding Examination

In the world of commercial construction, the relevance of welding examination can not be overemphasized. Welding inspection plays a critical function in ensuring the integrity, security, and durability of bonded frameworks. Provided the varied applications of welding in industries such as building and construction, auto, aerospace, and shipbuilding, the demand for rigorous high quality control procedures is extremely important. Correct inspection makes certain that welds fulfill specified codes and requirements, which is necessary for protecting against structural failures that can cause catastrophic effects.

The process of welding inherently includes complicated variables, consisting of temperature, product properties, and ecological conditions, every one of which can influence the quality of the weld. A thorough examination recognizes issues such as splits, porosity, and incomplete fusion, which can jeopardize the stamina and reliability of the weld. By identifying these concerns early, corrective activities can be taken, thereby minimizing the threat of failure and associated prices.

In addition, welding inspection adds to regulatory compliance, as many sectors are controlled by stringent safety standards and guidelines. Failure to abide by these laws can result in lawful responsibilities and financial charges. Inevitably, welding evaluation not just safeguards physical frameworks but also protects human lives and maintains industry credibilities.

Trick Welding Inspection Techniques

Although welding evaluation is critical to guaranteeing the quality and safety of bonded frameworks, it is the details approaches employed that identify the performance of the evaluation process. Trick welding inspection techniques can be extensively categorized right into non-destructive testing (NDT) and destructive testing.

Magnetic bit testing and fluid penetrant testing are surface assessment approaches utilized to situate surface and near-surface defects. These extensive inspection techniques make sure that welds fulfill sector standards and security demands, therefore ensuring structural stability and performance.

Function of Qualified Assessors

Licensed assessors play a crucial role in the welding inspection process, guaranteeing that all welds follow rigid market requirements and security policies. Their knowledge is vital in determining flaws or irregularities that may compromise the structural honesty of a weld. By diligently analyzing each weld, certified inspectors aid protect against possible failings that might result in expensive repair work or unsafe mishaps.

To end up being certified, inspectors must undertake extensive training and screening, which acquaints them with different welding techniques, products, and testing methods. This thorough understanding allows them to evaluate weld top quality successfully and make notified judgments about their safety and security and dependability. Certified assessors are skilled in interpreting plans and specifications, making sure that the welding work lines up with the task's style needs.

An important component of their role is to document their searchings for completely, providing an in-depth record of the assessment procedure. This documentation is critical for traceability and responsibility, functioning as an official record of conformity with sector standards. Licensed assessors also play a crucial role in assisting in interaction in between project stakeholders, using recommendations and insights to boost welding practices and results. Their payment is crucial in keeping high levels of high quality and security in welding procedures.

Tools Made Use Of in Welding Examination

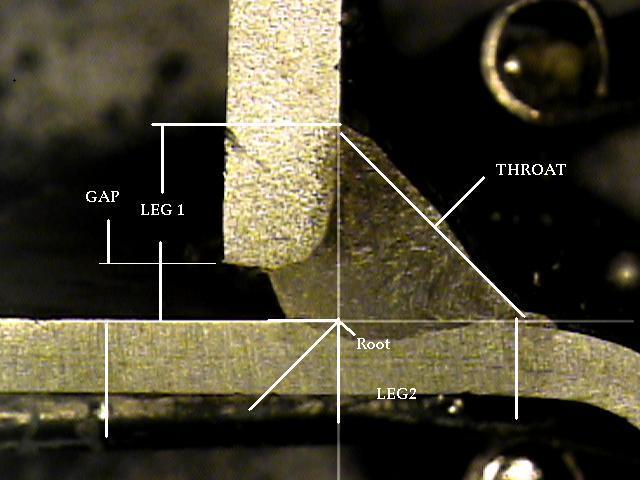

Welding assessors count on a range of specialized tools to perform their duties effectively, making certain each weld fulfills the needed standards. Among these devices, aesthetic evaluation aids like multiplying glasses and mirrors are essential, allowing inspectors to very closely take a look at welds for surface defects such as splits, porosity, and undercut. Calipers and fillet weld assesses are vital for measuring weld measurements to confirm compliance with style specifications.

Advanced devices prolong past visual help, including non-destructive screening (NDT) devices. Ultrasonic screening gadgets are pivotal in identifying subsurface problems, utilizing audio waves to reveal internal stoppages without jeopardizing the weld's honesty. Similarly, radiographic screening uses X-rays or gamma rays to capture photos of a weld's inside, highlighting potential flaws.

Magnetic bit screening is another essential device, particularly for identifying pop over here surface area and near-surface stoppages in ferromagnetic materials. By using ferrous particles and magnetic areas, examiners can determine flaws that may or else be invisible.

Dye penetrant assessment is often utilized for non-ferrous products, giving a contrast-enhanced visual check for surface-breaking flaws. Welding Inspection Madison. With each other, these tools allow welding examiners to adequately assess weld quality, making certain safety and reliability in various applications across markets

Making Sure Architectural Honesty

Welding procedures must comply with recognized standards and codes, such as those defined by the American Welding Society (AWS) or the International Company for Standardization (ISO) These guidelines guarantee that the welds can withstand functional stress and anxieties and ecological elements. Qualified and accredited welders play an important duty in this process, as their knowledge makes certain that methods are applied appropriately, lessening defects such as fractures, porosity, and insufficient combination.

Post-weld examination is one more crucial element of validating structural stability. Non-destructive screening (NDT) methods, consisting of ultrasonic screening and radiographic testing, are utilized to detect subsurface problems without endangering the bonded framework. These inspections verify that the welds fulfill the required quality criteria, giving guarantee of their longevity and dependability. Inevitably, ensuring structural stability in welding not just safeguards human lives yet also secures financial investments and enhances the longevity of engineered frameworks.

Final Thought

The fundamentals of welding examination more helpful hints are necessary for maintaining the top quality and security of bonded structures. The usage of specialized tools additionally enhances the examination process, inevitably protecting human lives and lengthening the life expectancy of bonded constructions.

Welding examination plays an important role in making sure the integrity, security, and durability of welded structures.Although welding examination is vital to making certain the quality and safety and security Homepage of bonded structures, it is the details methods utilized that establish the effectiveness of the assessment procedure. Trick welding assessment techniques can be broadly classified right into non-destructive screening (NDT) and devastating screening.Qualified examiners play a pivotal function in the welding examination procedure, ensuring that all welds abide with rigorous sector requirements and security regulations.The fundamentals of welding examination are crucial for maintaining the quality and security of welded structures.